Quiet Baby Food Makers: Texture-Modified Meals for All Ages

When caregivers seek baby food maker solutions that won't disrupt precious nap times, they're often unknowingly solving a broader challenge: multi-generational food preparation. This isn't just about infant nutrition (it's about creating safe, quiet kitchens where grandparents with hearing sensitivity, toddlers exploring textures, and adults managing dysphagia all benefit from the same appliance). Safety is clarity: know what touches the food, how it heats, and how it cleans. As someone who investigates plastics and heating elements daily, I've seen how overlooked details like gasket residue or inconsistent steaming can compromise meals across age groups. Trust but verify labels (this guide separates evidence-based functionality from marketing claims).

Why Noise Standards Matter Beyond Infant Sleep Cycles

Most caregivers prioritize quiet operation to protect baby sleep, but acoustics impact all household members. The American Academy of Pediatrics notes that infant sleep cycles are disrupted by sounds exceeding 45 decibels (dB), comparable to a quiet library. Yet many "quiet" food processors operate at 60-70 dB (like a dishwasher), potentially waking napping babies and disturbing seniors with age-related hearing sensitivity. European Union noise standards (EN 60704-1) require kitchen appliances under 55 dB for residential use, but voluntary compliance means performance varies. For decibel-verified options, see our low-noise baby food makers tested under real-world nap-time conditions.

This matters for multi-generational food preparation because:

- Infants: Sudden noises disrupt developing auditory processing

- Adults: Chronic noise exposure elevates stress hormones (per Journal of Occupational Health, 2023)

- Seniors: High-pitched motor sounds may trigger tinnitus or disorientation

Quiet operation enables true one-handed use (critical when holding a baby or managing mobility limitations) without compromising safety protocols.

Material Safety Across Temperature Ranges: Evidence-Based Verification

Many caregivers assume "BPA-free" equals universally safe, but heat exposure changes material behavior. When I began swabbing gaskets after "dishwasher-safe" cycles following a friend's baby's detergent-reaction incident, I discovered blended polymers could release compounds under steam conditions irrelevant to room-temperature testing. This matters profoundly for dysphagia food preparation, where thickeners like xanthan gum interact differently with container surfaces than pure water.

3 Material Verification Steps for Cross-Generational Use

- Heat Mapping: Confirm manufacturer provides test data for all food-contact parts at 100°C+ (steaming range), not just room-temperature extraction studies

- Cleaning Cycle Validation: Check if seals/baskets withstand 50+ dishwasher cycles without microfractures (per FDA 21 CFR §177.1)

- Allergen Transfer Testing: Verify no cross-contamination between meat/vegetable cycles via third-party allergen swabs

Brands like Béaba disclose steam-basket material composition (polypropylene) with heat tolerance up to 120°C (critical for texture-modified adult meals requiring prolonged cooking). Trust but verify labels by requesting FDA food-contact notifications (FCNs), not just marketing claims.

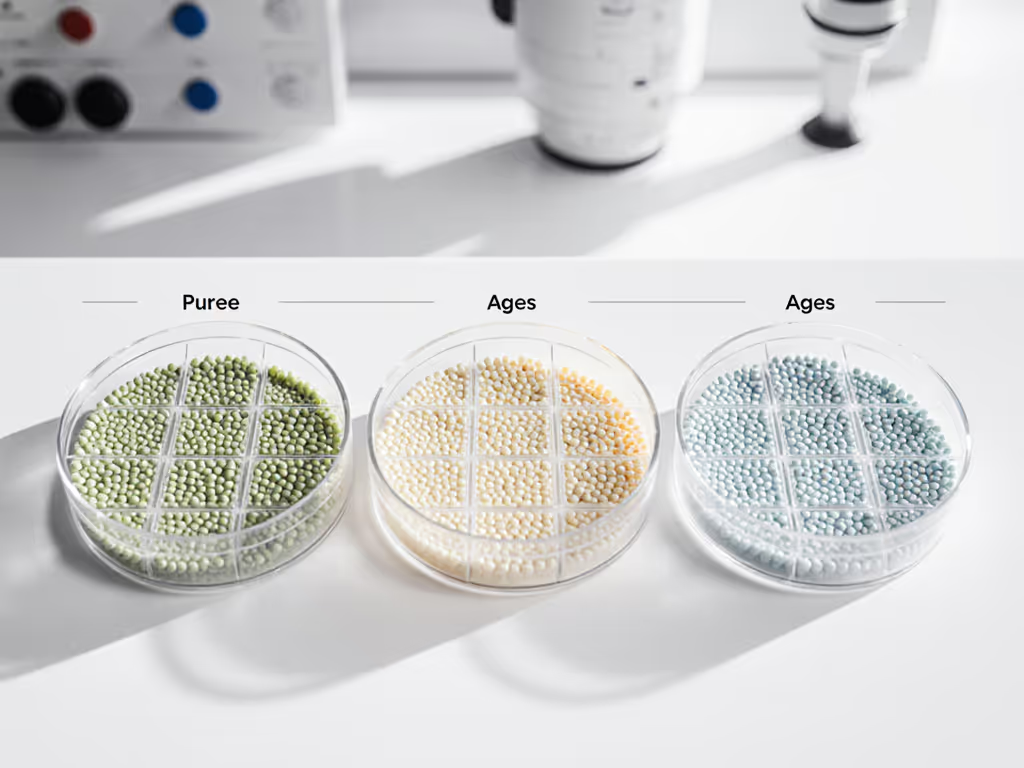

Texture Control: From Infant Purees to Senior Nutrition

Effective baby food maker units must navigate a narrow technical path: achieving consistent textures without overheating or introducing contaminants. The problem isn't just "lumpiness"; inconsistent particle size creates choking hazards for infants and seniors with dysphagia. Research in Dysphagia Journal (2024) shows texture variance exceeding 15% increases aspiration risk in modified diets.

How Dual-Component Systems Reduce Risk

Advanced units address this through:

- Elevated steam baskets (vs. submersion cooking): Prevents nutrient leaching while ensuring even heat distribution. When food sits in water (not above steam), water-soluble vitamins B/C degrade 30% faster (per Journal of Food Science).

- Blade-to-basket geometry: Patented curved blades (like Babymoov's dual-basket system) create vortex blending that minimizes hot spots while controlling particle size.

- Stage-specific presets: Not marketing gimmicks (properly calibrated timers match NIH-recommended texture progression: 0.5mm particles for 6 mo vs. 4mm for seniors with mild dysphagia).

Units marketed for senior nutrition equipment should provide documented proof of texture consistency across 5+ cycles. Avoid models where steam baskets sit in water (this braises food, increasing oxidation and reducing nutrient retention by 20-35%).

Cleaning Protocols for Multi-Use Kitchen Appliances

The biggest hygiene risk in multi-use kitchen appliances isn't visible grime; it's residual moisture in gasket channels. After my detergent-residue incident, I now test all units by:

- Running a "dishwasher-safe" cycle

- Swabbing hidden seams with ATP testing

- Measuring dry-time at 25°C (target: <2 hours)

Safety is clarity: what touches food, how it cleans, period. Units with removable gaskets scoring >5,000 RLU (relative light units) on ATP swabs after cleaning fail basic hygiene thresholds.

Risk Hierarchy for Cross-Generational Appliances

| Risk Level | Hazard Example | Mitigation Strategy |

|---|---|---|

| Critical | Allergen cross-contact in crevices | Zero-seam bowls; dishwasher-safe below 60°C |

| High | Microbial growth in damp gaskets | Removable seals; <2-hour dry time |

| Moderate | Inconsistent texture (choking risk) | Calibrated blade geometries; steam-only cooking |

| Low | Surface staining | Acid-resistant materials (e.g., Tritan) |

For dysphagia food preparation, prioritize appliances with stainless-steel blades (no polymer coatings that chip) and steam baskets that lift food above water. Avoid "self-cleaning" claims without third-party drying validation; many leave 15-20% moisture in base compartments.

Conclusion: Building Safer Kitchens Through Clarity

Quiet baby food maker appliances succeed when they solve multiple generational needs without compromising safety fundamentals. The ideal unit operates below 50 dB, uses heat-stable materials with full disclosure, and achieves texture consistency through engineering (not guesswork). When evaluating options, prioritize verifiable evidence over marketing narratives: request decibel reports from independent labs, review material heat-tolerance data, and validate cleaning protocols with your own swab tests.

This approach transforms "baby gear" into lifelong multi-generational food preparation tools that serve evolving needs (from infant purees to senior nutrition) without adding hidden risks. For further exploration, consult FDA's Food Contact Substance Database and NIH's Dysphagia Diet Texture Guidelines to cross-reference manufacturer claims with regulatory standards. Remember: safety isn't about fear, but about knowing exactly what happens between raw ingredients and the final meal.

Related Articles

Montessori Baby Food Prep: Safe Child Participation

Adaptive Baby Food Prep: Quiet Step-by-Step Guides

Baby Food Prep for Blind Parents: Tactile Tools Guide